BIODIESEL

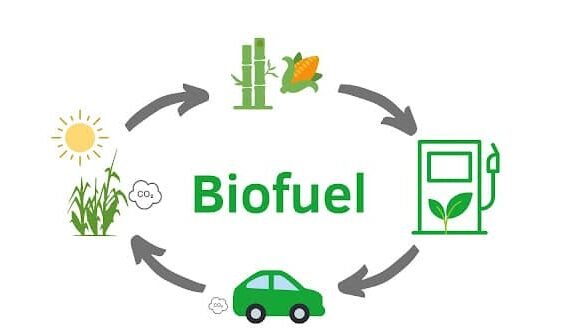

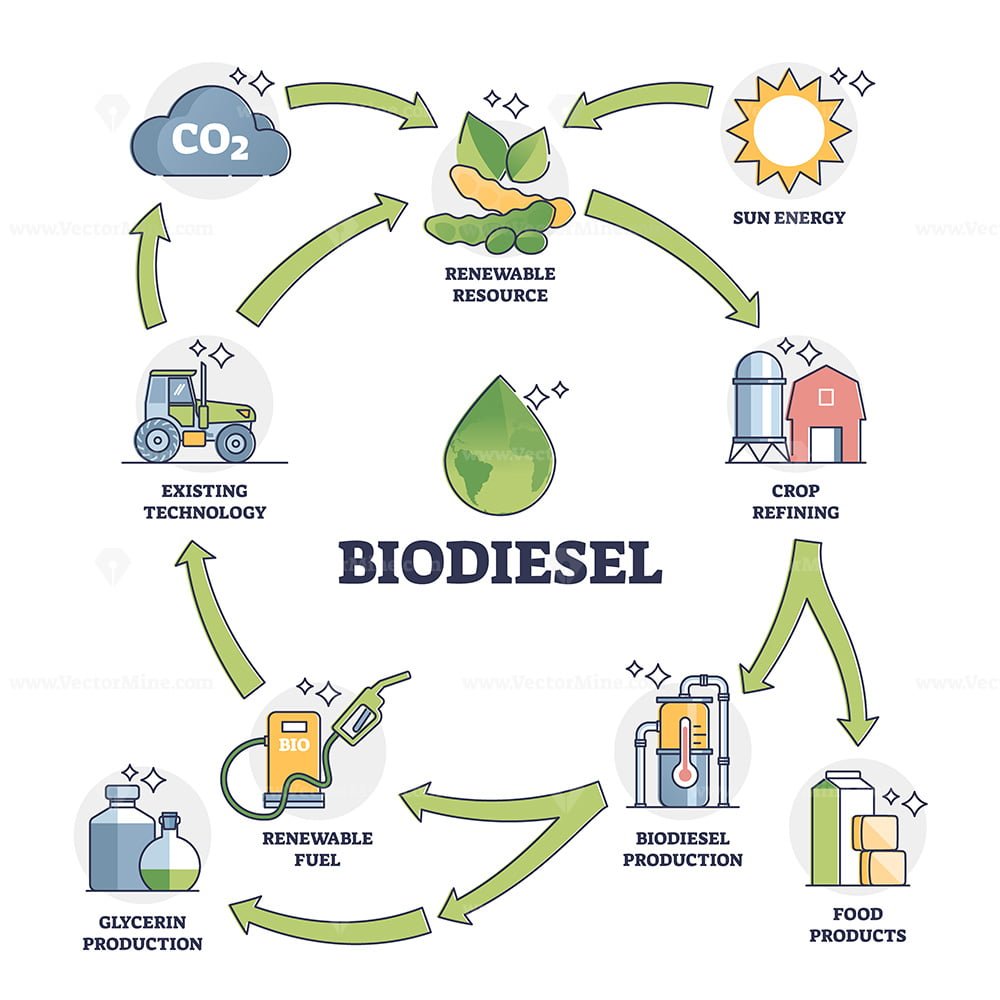

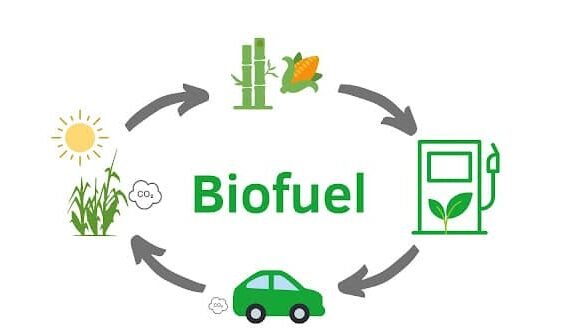

Biodiesel is a liquid fuel produced from renewable sources, such as new and used vegetable oils and animal fats and is a cleaner-burning replacement for petroleum-based diesel fuel. Biodiesel is nontoxic and biodegradable and is produced by combining alcohol with vegetable oil, animal fat, or recycled cooking grease.

Like petroleum-derived diesel, biodiesel is used to fuel compression-ignition (diesel) engines. Biodiesel can be blended with petroleum diesel in any percentage, including B100 (pure biodiesel) and, the most common blend, B20 (a blend containing 20% biodiesel and 80% petroleum diesel).

Webmaster : Phatr Sirisathaworn M.5/5 No.3

Reference : https://www.energy.gov/eere/bioenergy/biofuel-basics